The most beautiful service one can do to a person is to help him to help himself. (by R.W. Emerson)

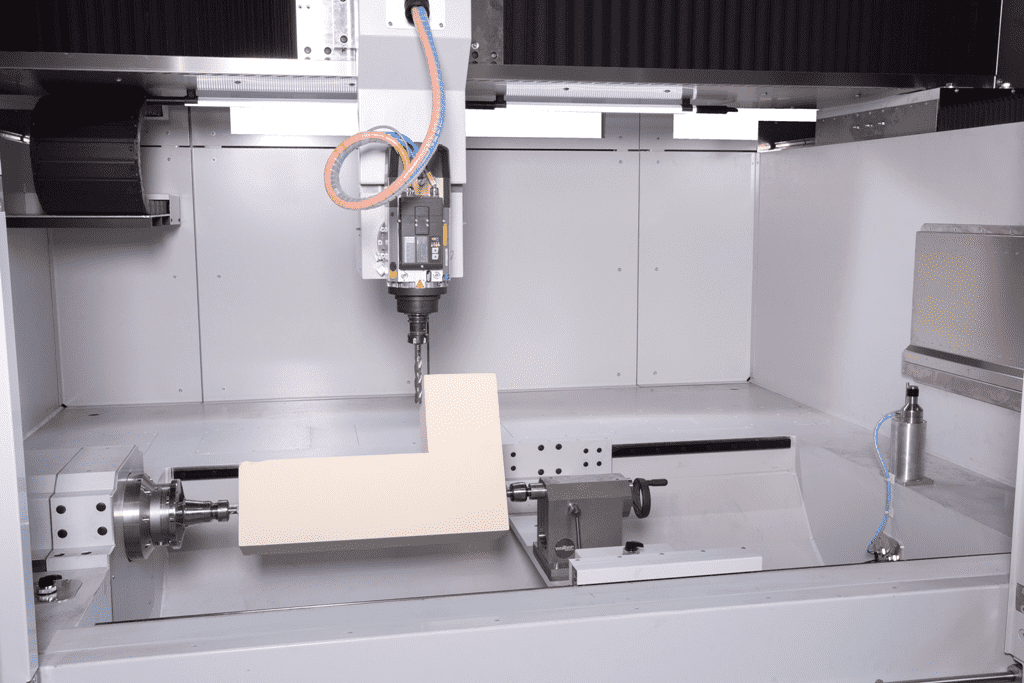

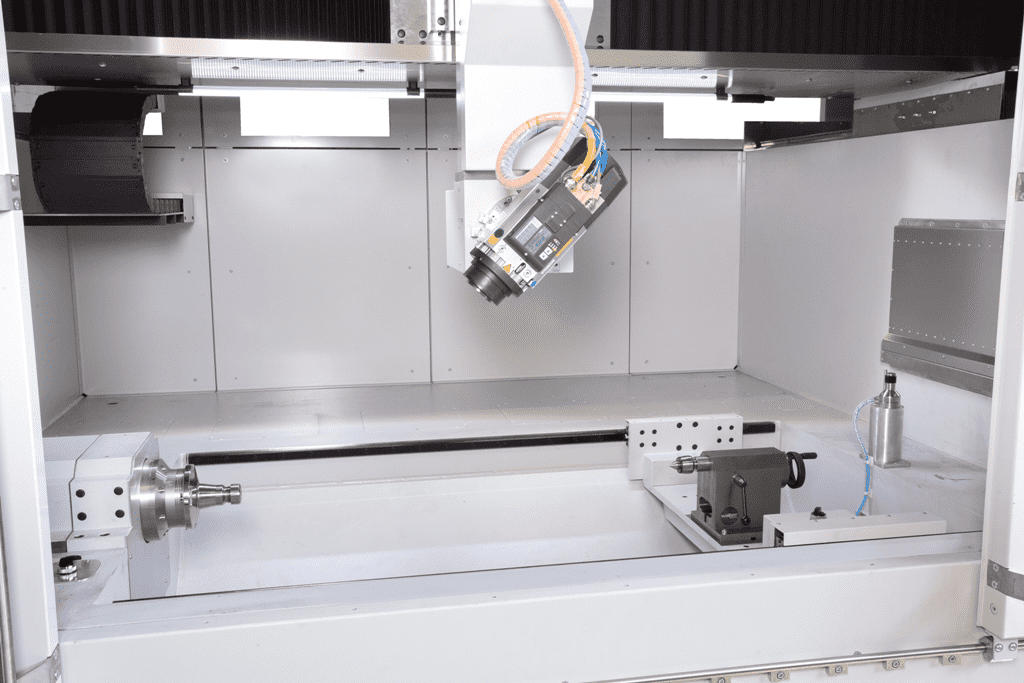

This principle has been written on his flag by one of our customers. In nine decades, our customer has become one of the most important specialists in orthopedic technology worldwide. Currently our new Porta Pro machine series has been developed with this customer with the “Pro” for prostheses. Until now it was the case that only the prosthesis was milled. Through the development of the 5-axis Porta Pro, the digitized body of humans can now be milled and the prostheses can be directly adjusted without the patient having to constantly try on them. Block material up to a size of 700 x 700 x 1200 mm can easily be processed 5-axis.

Technical Data

- • Stable, highly rigid steel construction

• Substructure completely closed, with mineral cast filling

• Travel range: 1950x500x650 mm (X/Y/Z)

• Working area: 1300x500x650 mm (X/Y/Z)

• Completely closed machine housing with front door elements

• Doors can be opened and closed pneumatically

A-Axis

• Divider (A axis):

-

– Backlash: < 0.01°

– Max. rated torque: 490 Nm

– Torsional stiffness: 255 Nm/arcmin.

– max. axial load : 11,760 N

– permissible tilting moment: 1,764 Nm

B-Axis

• Swivel spindle (B axis):

-

– Pivoting range: +/- 50°

– Backlash: < 0.01°

– Torsional stiffness: 97 Nm/arcmin.

– max. axial force: 4150 N – tilting rigidity: 550 Nm/arcmin

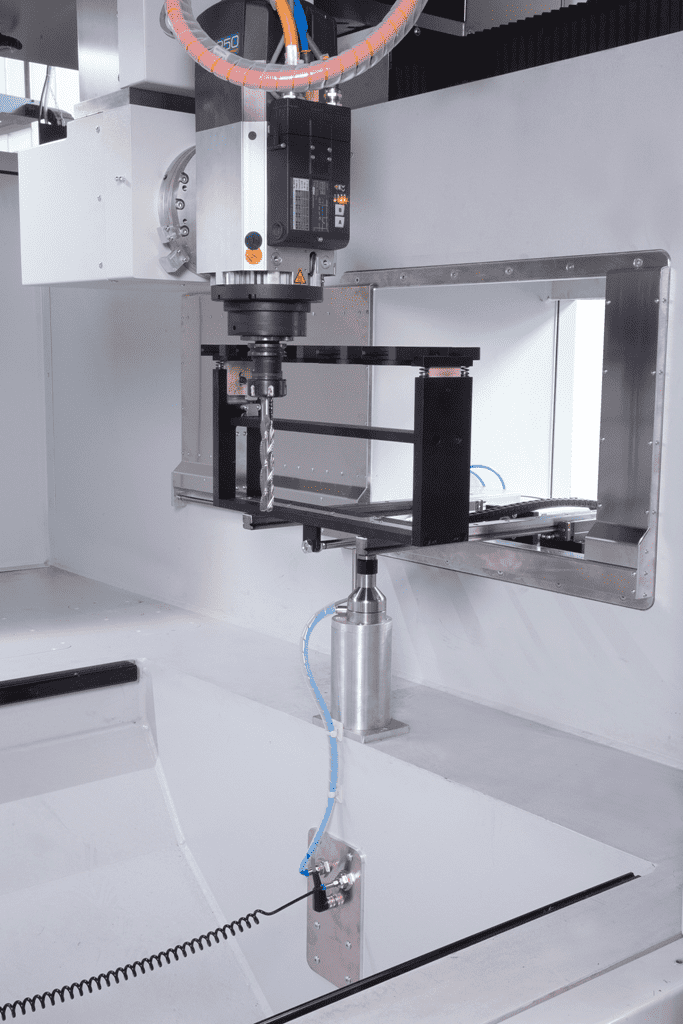

Toolchanger

• Tool changing system:

-

– pickup system

– 10-fold

– pneumatically – and swings out

– incl. measuring cell for automatic tool length measurement

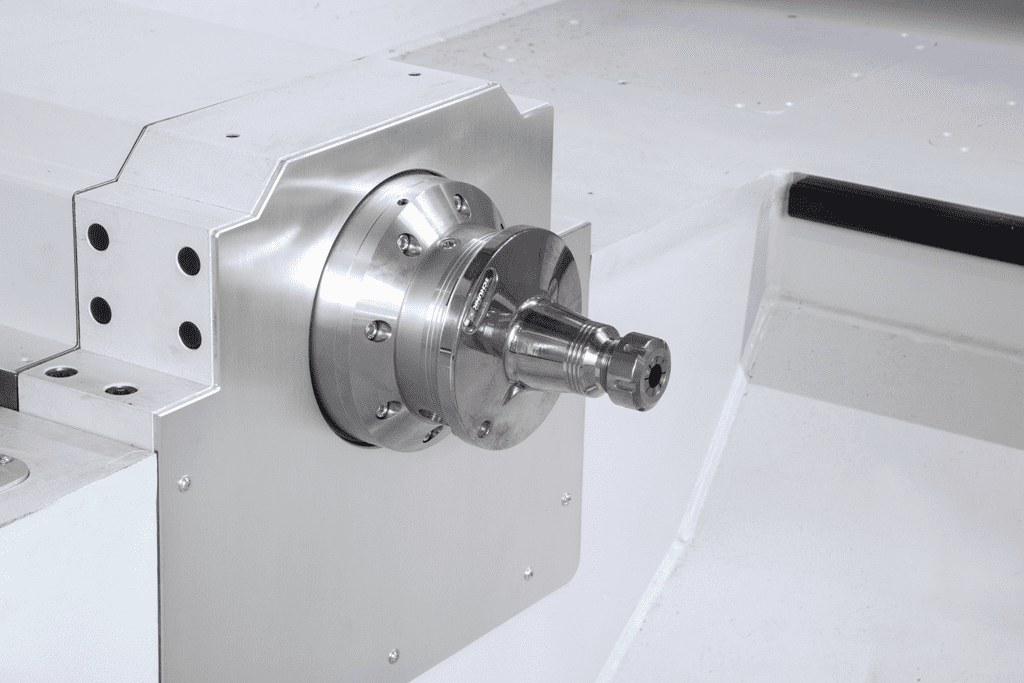

Clamping System

• Clamping system:

-

– Schunk NSE