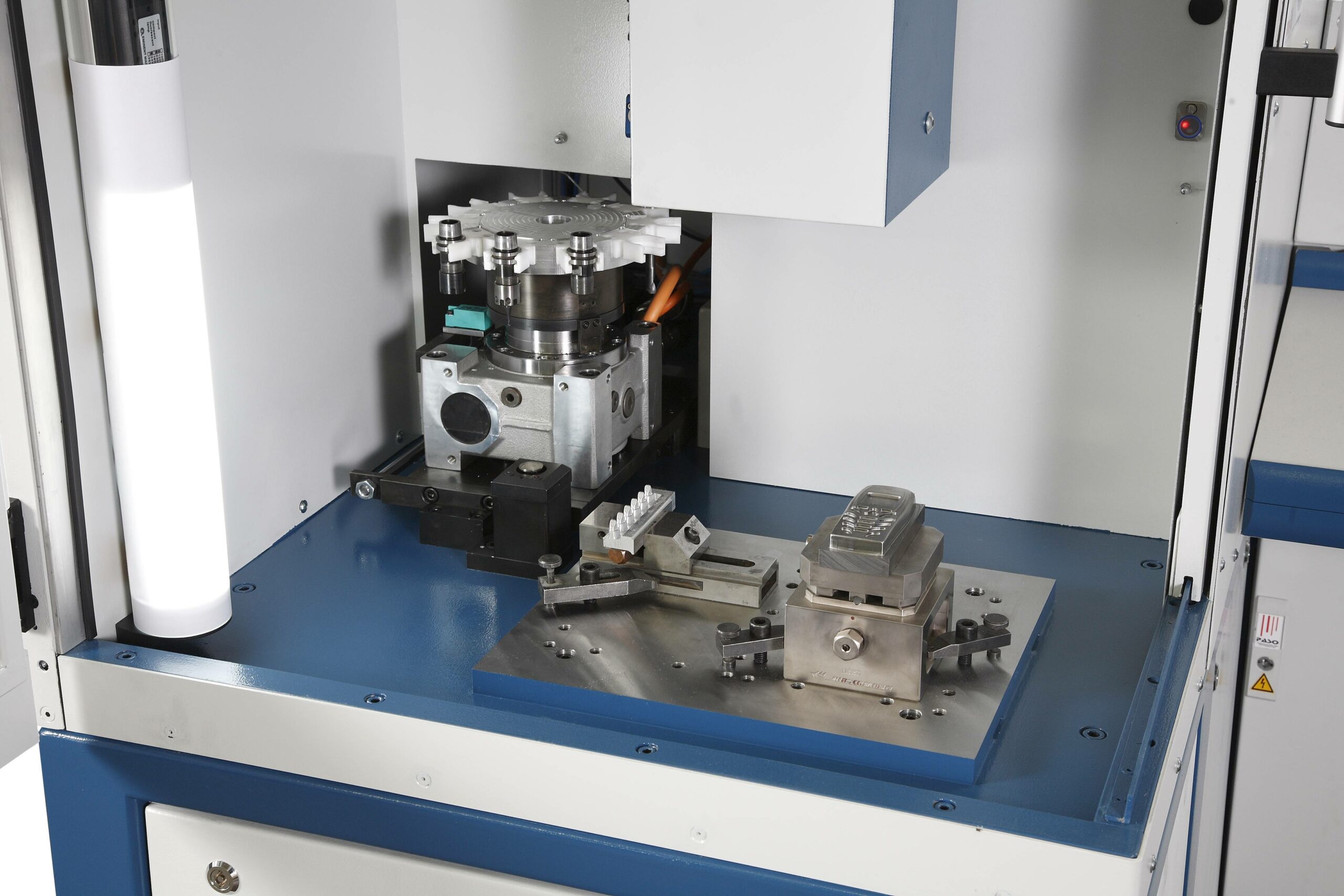

• The Micro series is based on a highly compact 3-axis machine with a fixed table (single – column machine) and special precautions to machining highly abrasive materials such as: – graphite – ceramics – zircon All other materials can also be processed.

• with a working area of 300 x 300 x 300mm and installation dimensions of 800 x 1405 x 1900mm (without control panel), it fits through every door

• The Micro series is based on a concept that can be used variably, which can be specially modified according to customer requirements.

• Applications are, among others, micro-machining, watch and jewelery industry, and dental technology

• It is also easy to create fine engravings or electrodes in copper and graphite.

Info

– variable concept

– universal use

– Precision for micromachining

– special adaptation to customer requirements can be realized

Pictures

Video

Technical specifications

– Workspace (X/Y/Z): 300 x 300 x 300 mm

– Substructure: either open or completely closed substructure with mineral cast filling

– Control: optionally Andron, Eckelmann, Heidenhain

– Drive: digitally controlled AC servo;

– Positioning accuracy: min. +/- 4µm (according to VDI 3441)

– Repeat accuracy: min. +/- 2 µm (according to VDI 3441)

– Vorschub / Eilgang: Standard bis 30 m/min.

– Spindelleistung: bis HSK 32

– Spindle cooling system: dry cooler

– Tool changing system: standard 10-fold plate

– manual control panel

– Installation dimensions: on request

– Weight: on request

Download

Flyer Micro Serie:

Download