Paso offers a number of sensors, which are for ex.:

• Measure and compensate for height differences

• Touch workpiece edges and reduce set-up times through fixture compensation

• Digitize surfaces and create point clouds,

which then over surface repatriations can be processed further

• Camera systems for the automatic recognition of reference marks

• Laser systems for measuring tool geometry and length

and much more ….

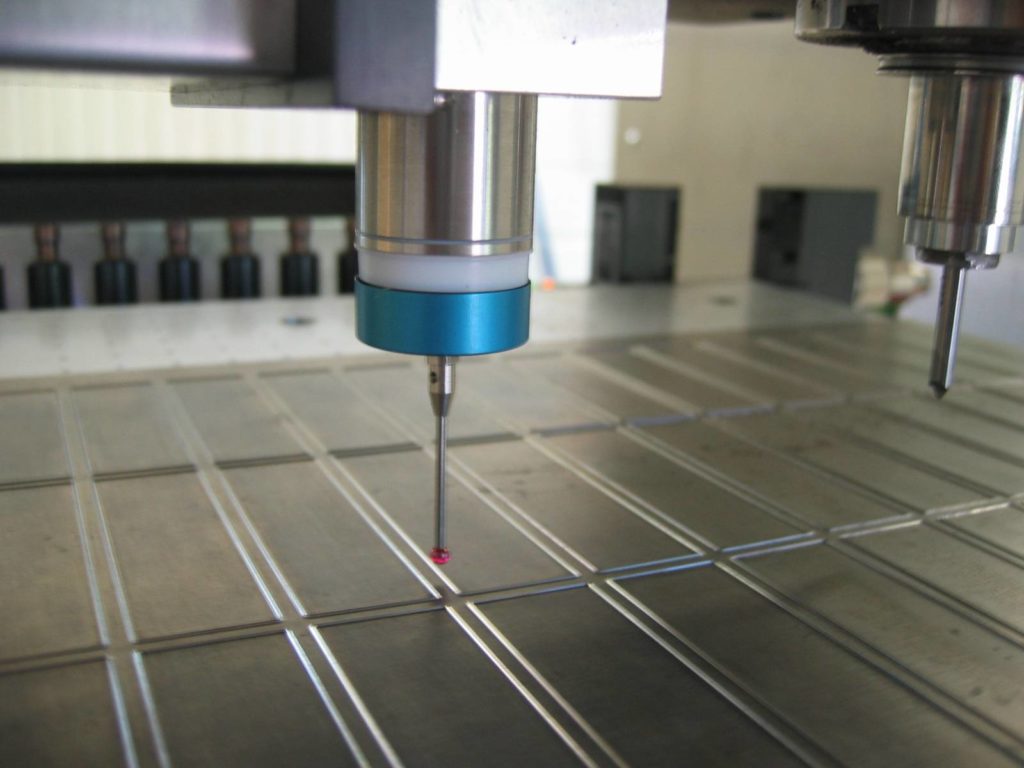

Surface sensing 2D

- 2D, tactile sensing

- automatic swivelling

Surface sensing 3D

- data transfer: by cable

- turn on method: tracer pin deflection

- effective & safe data transfer

- patented On/Off System for changing parts

- fast touch of the work piece edge, thereby lowered set-up times

- increase of the quality and safety

- highest repeatability

- Easy installation and usage

- predetermindet breaking point technology

- Lagerung auf Halbkugel, dadurch stabile Nulllage

- turn on method: tracer pin deflection

- deflection in X/Y: 14°

- defection in Z: 4,0 mm or 0,15”

- repeatability accuracy: +/- 1 µm (50 mm tracer pin)

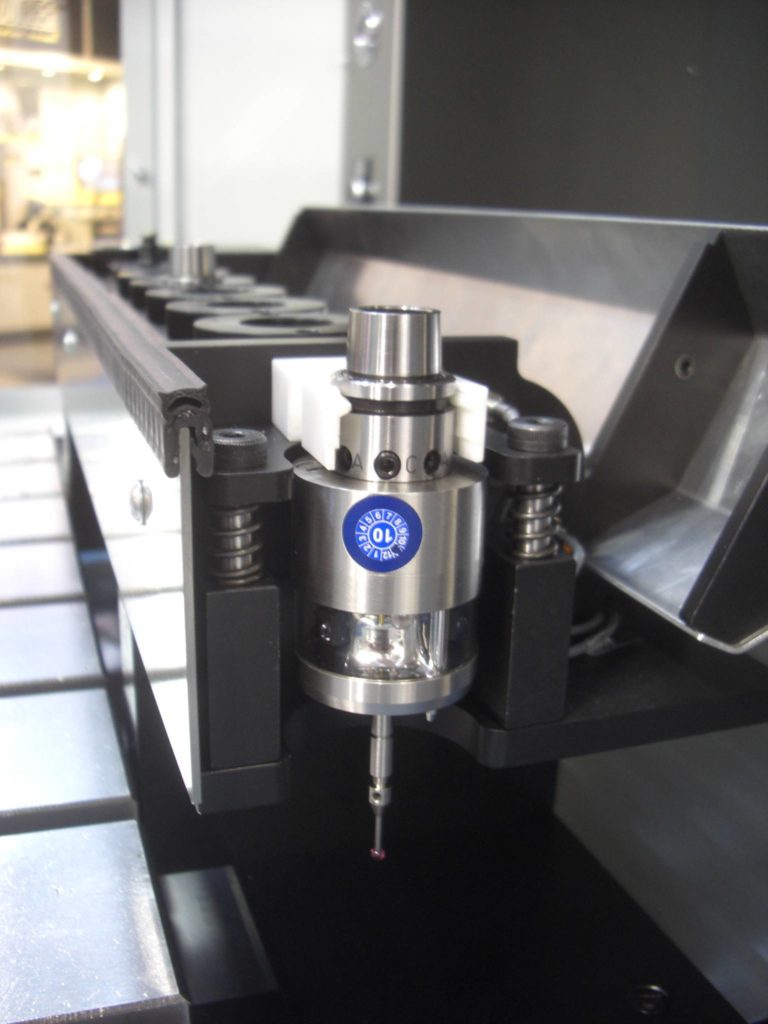

Surface sensing 3D

- turn on method: tracer pin deflection

- effective & safe data transfer

- patented On/Off System for changing parts

- fast touch of the work piece edge, thereby lowered set-up times

- increase of the quality and safety

- highest repeatability

- Easy installation and usage

- predetermindet breaking point technology

- Lagerung auf Halbkugel, dadurch stabile Nullage

- turn on method: tracer pin deflection

- deflection in X/Y: 14°

- defection in Z: 4,0 mm or 0,15”

- repeatability accuracy: +/- 1 µm (50 mm tracer pin)

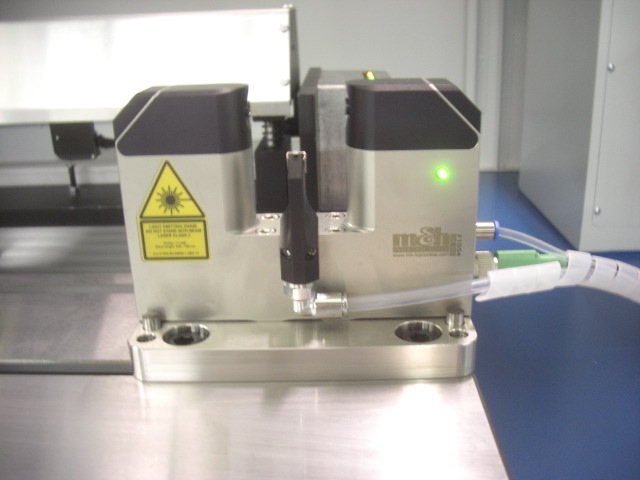

Digitize by laser

- Conoprobe is a contactless measuring sensor. Changeable lenses allow for a broad usage with different measuring widths.

- available lenses focal lengths: 25mm, 50mm, 75mm, 100mm, 125mm, 150mm, 300mm

- Data export to: Excel, ASCII, BMP, JPEG, VRLM

- Absolute accuracy: depending on the lens used <0,5µm to 25µm

- Repeatability:0,1µm to 15µm

- reliable data from sharp slopes and blind holes: ≤ 85°

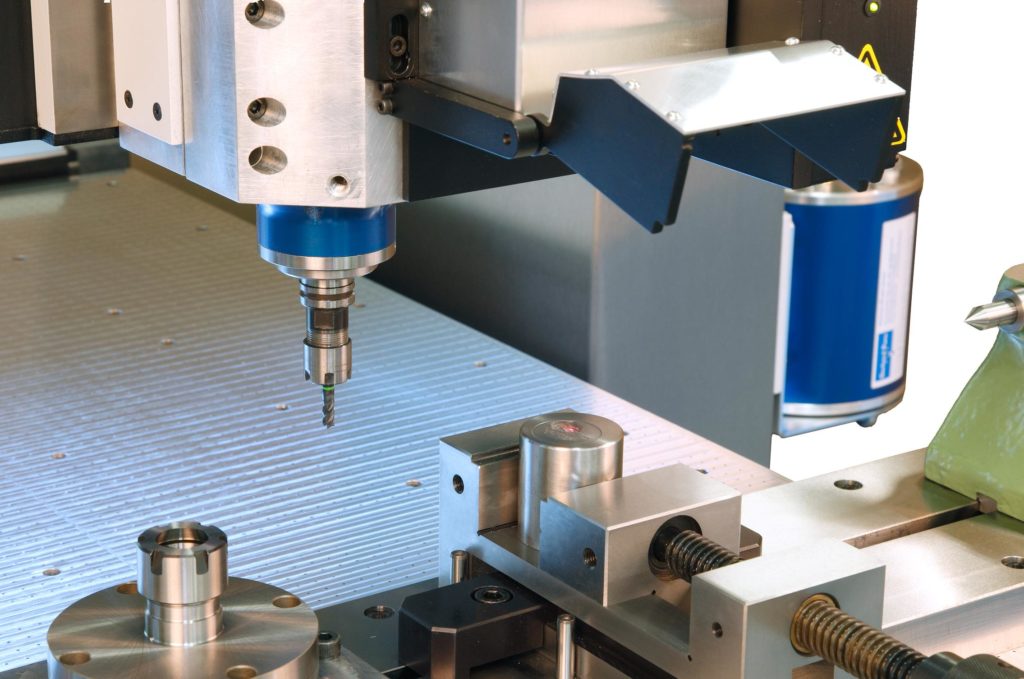

Tool measurement via Laser

- Min. tool diameter 0,006 mm

- Max. tool diameter: 35 mm

- Repeatability: +/- 2 µm

Camera system for automatic reference mark recognition

- The reference marks are recognized independently of the rotational position, i.e. with any component orientation

- monochrome

- Resolution: 1280 x 1024 Pixel

- Field of View: 65 x 50 mm

- Lighting: LED-Darkfield, white

- Accuracy: +/- 0,1 mm in X- and Y- Axis

- The achievable accuracy can be achieved by optimizing the optical

- Parameters such as field of view size, object distance and camera resolution can be further improved.

- Object distance: 130 mm

- incl. Cameracable, USB

- incl. Calibration plate

- IP65

- 1 lens

- LED-Incident light

- 1 x Softwarelicese E.SEE for image evaluation and communication to the machine control – incl. Bracket for the camera