Market requirements with regard to precision in milling operations increase from year to year.

Whether it’s in tool and mould making,

micro-machining or medical technology, tolerances are getting increasingly tighter.

The demands made on machine technology are

therefore also more complex and costly.

High-precision drive and control technology in conjunction with precision guides are certainly the basis for precision manufacturing but regrettably they are not always the perfect solution.

All users are aware of the issue of temperature drift on processing machines in their day-to-day work, especially with the precision manufacturing of parts with a tight tolerance and this is often a problem that is very difficult to solve.

There are many approaches both inside and outside the machine to control this temperature fluctuation.

On the one hand, machines for precision manufacturing are installed in air-conditioned rooms or temperature tables in the control system should compensate for the geometric shifts; others try to imply that they have a stable temperature through the use of appropriate base materials, such as granite, and are therefore resistant to fluctuations in the ambient temperature.

It is often forgotten that the axis guide systems and their powertrains are still made of steel and firmly fixed to the base.

Highs and lows may occur rather than stable positioning and traversing movements on the condition that the body should remain stable and the guide systems should be subject to unavoidable linear expansion.

The other option of stabilising the ambient conditions is costly and time-consuming.

A further aspect of temperature drift is the heat sources within the machine.

There are approaches and solutions here that partially provide these heat sources with cooling systems at various points, such as milling spindles, driven nuts, etc., but do not detect the entire machine body.

PASO is taking the opposite approach with its latest development.

he machine itself is air-conditioned so there is no need for the machine environment to be air-conditioned or empirically determined compensation tables to offset the shifts.

The basis for this is a climate system with a heating and cooling function that is integrated into the machine.

The entire machine body and working area are maintained at a constant temperature using sophisticated air and cooling channels.

It’s not just during the day that an increase in temperature is eliminated but the machine also remains at a constant temperature overnight and at the weekend if the room temperature drops. A static shift in the machine geometry as the greatest unknown factor is therefore ruled out and the machine requires no time-consuming warm-up phases.

Initial experiences with the HSC1250, as well as and specifically under heavily fluctuating ambient temperatures, demonstrate the accuracy of this approach and are a further example of the fact that PASO has focussed on the demands of the market for many years and has reacted to its requirements with innovative solutions. This once again underlines PASO’s achievement potential and the focus of the business since its inception, incorporated into the corporate philosophy, is to supply its customers with a project-based solution rather than an off-the-peg standard machine.

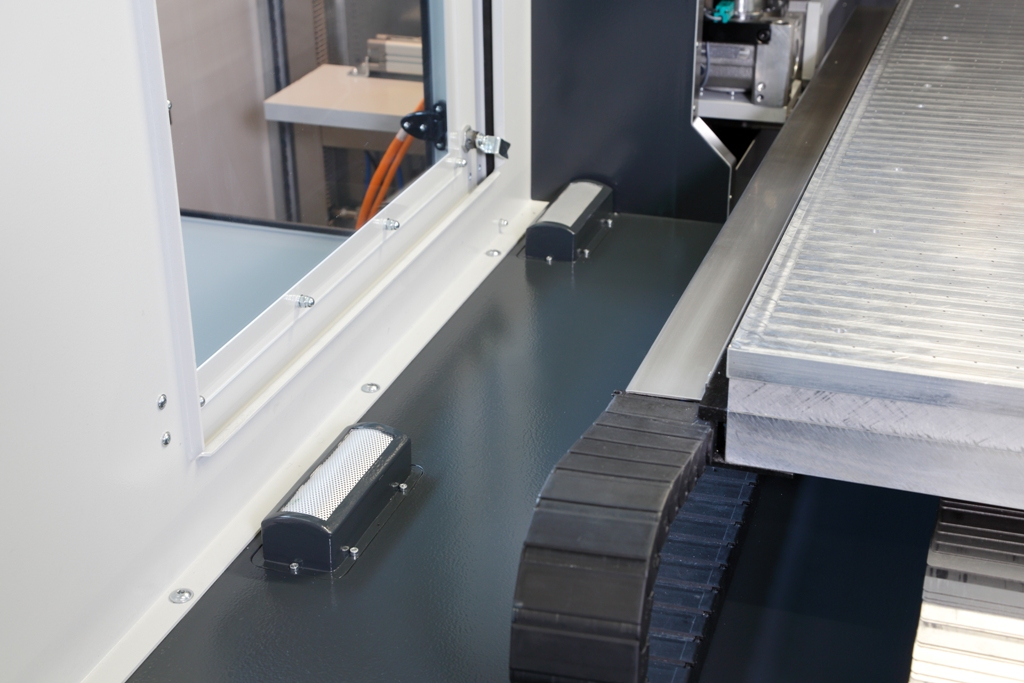

Climate system on the machine

Cooling channels integrated in the work area